Linear Garage Door Repair (Troubleshooting)

Troubleshooting Chart

| Lamp Flashes Trouble Code | Problem | Cause | Remedy |

|---|---|---|---|

| 1 FLASH | No Problem | Remote control entered into memory | Add any additional remote controls (MegaCode™ type only) |

| 2 FLASHES | Door won’t close | Shorted wall station wires | Check wall station wires. Be sure both are connected to the terminal screws. Check for a staple in the wall station wires. Remove any staples compressing the wire |

| 3 FLASHES | Door won’t close | Safety beam obstacle | Check for obstacles. Align the safety beam |

| 4 FLASHES | Door reverses or won’t open or close | Open or Close force exceeded | Check for obstruction or binding of garage door. Perform fi eld reset (Section 19) if necessary. |

| 5 FLASHES | Door won’t open | Remote was activated while vacation switch was locked | Unlock vacation switch on wall station |

| 6 FLASHES | Motor ran longer than 30 seconds | Mechanical or electronic failure | Call Technical Services Group for assistance |

| 7 FLASHES | Limit error | Encoder has detected error or down limit set above up limit. | Re-set the open and close limits. If error occurs again, call Technical Services Group |

Adjusting the Force Factor (Installation Option, Normally Not Used)

The operator uses the peak force measured during each of the last four complete cycles plus a “force factor” to calculate the maximum allowed force setting for the current door cycle. If the calculated maximum force setting is exceeded during the current door cycle, the operator reacts to the obstruction. As door hardware conditions change over time with weather and wear, the calculation of the maximum door force setting using the four cycle running average will compensate for the current conditions of the installation.

The door force is preset for the lowest amount of pressure on an obstacle to detect an obstruction. THE FACTORY SETTING IS OPTIMIZED FOR MOST INSTALLATIONS.

Changing the Force Factor Setting

| FORCE FACTOR INDICATOR TABLE | |

|---|---|

| GREEN ON | LOW FORCE FACTOR |

| RED & GREEN ON | MEDIUM FORCE FACTOR |

| RED ON | HIGH FORCE FACTOR |

As an installation option, the operator’s “force factor” can be adjusted to change the amount of pressure exerted on an obstacle before the operator reacts to the obstruction.

- Press both the UP and DOWN buttons for three seconds. The red and green indicators and operator’s light will flash twice.

- Use the UP or DOWN buttons to set the force factor. Pressing the UP button increases the force factor, pressing the DOWN button decreases the force factor

- After selecting the force factor, press the LEARN button to store the setting and exit setup. The red and green indicators and the operator’s light will fl ash two times. (If the force factor is not set within one minute, the operator will return to normal operation at its previous force factor setting.)

- After changing the force factor setting, perform the Safety System Reversal Test.

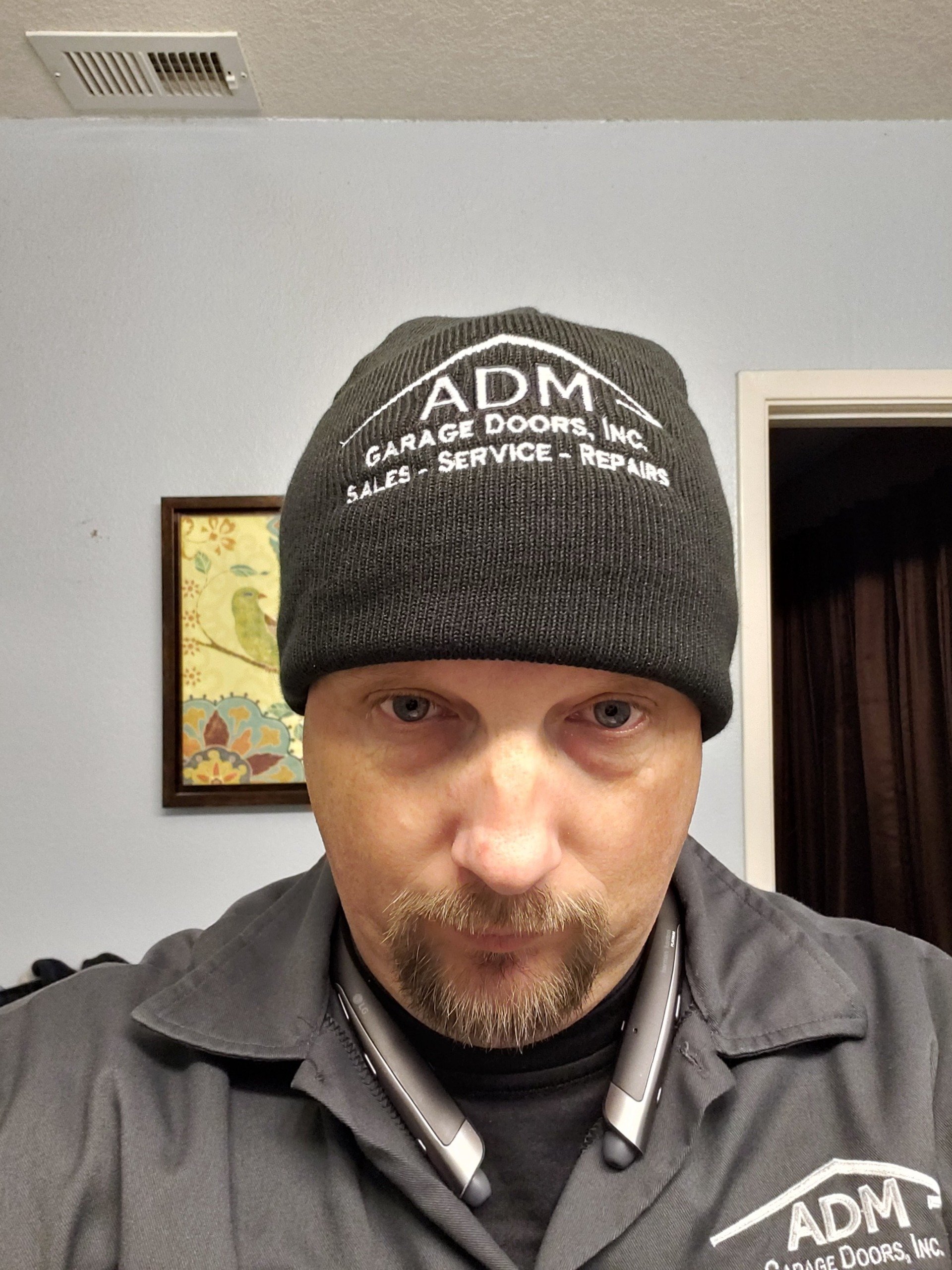

President

Top Salesman

Head Installer

Marketing Manager

President

Top Salesman

Head Installer

Marketing Manager

President

Top Salesman

Head Installer

Marketing Manager

READ WHAT OUR CUSTOMERS ARE SAYING ABOUT US!!

Slide title

Andre gave me exceptional advice over the phone regarding issues with my garage door not properly working even though I have a friend in the business that will be doing the job. He called me back on a Sunday to see how he could help with offering suggestions and solutions to my garage door situation. He is extremely knowledgeable, honest and trustworthy. I would definitely use his services and recommend him for any of your garage door needs. He is quick to respond and truly cares. A true gem in the industry!!

Robin Barca

Button

Slide title

Andre was very accommodating and easy to do business with. He came over soon after I called to replace a broken opener. He presented all of my options and their respective costs. I didn’t feel as though he was trying to up-sell me, but offered some suggestions to make my garage door opener last longer. He was very friendly and worked rather quickly. He cleaned up after himself, taking all the garbage and old equipment with him. I would highly recommend Andre at ADM for your garage door needs.

Richard Van Buskirk

Button

Slide title

Professional and meticulous installation. All service recommendations were explained thoroughly and justified. Workmanship and quality of hardware was top notch. Five Stars !!!

Frank Baccelli

Button

NEW!! Financing Now Available

Flexibility to pay for the best solution, instead of settling for a less costly "band-aid."

Quick application, see your options within seconds

Checking eligibility does not impact your credit score.

No late fees, no prepayment fees, & no origination fees.

CONTACT US

Contact us for super fast service!!

Contact Us

Thank you for contacting us. If you need immediate help please call us at 916-595-5355

We will get back to you as soon as possible.

Please try again later.

- By clicking SUBMIT you consent to receiving SMS messages."

- "Messages and Data rates may apply. Message frequency will vary"

- "Reply Help to get more assistance"

- "Reply Stop to Opt-out of messaging"

Cities We Serve

- Cameron Park/ Shingle Springs, CA

- Diamond Springs, CA

- El Dorado Hills, CA

- Fair Oaks, CA

- Folsom, CA

- Gold River/ Rancho Cordova, CA

- Granite Bay, CA

- Loomis, CA

- Orangevale, CA

- Rancho Murieta, CA

- Rescue, CA

- Rocklin, CA

- Roseville, CA

All content and images are protected under copyright laws. © 2007-2024 by ADM Garage Doors, Inc.

Privacy Policy | Warranty